Uphuhliso lwehlabathiishishini lamalaphuchain iye yandisa ukusetyenziswa kwempahla yonyaka ngamnye capita ukusuka 7kg ukuya 13kg, kunye nomthamo lilonke ngaphezu kwezigidi ezili-100 iitoni, kunye nemveliso zonyaka inkunkuma lufikelele kwizigidi ezingama-40 iitoni.Ngo-2020, ilizwe lam liza kuphinda lisetyenziswe iitoni ezizizigidi ezi-4.3 zeempahla ezilukiweyo, kwaye imveliso yemicu yemichiza iya kudlula iitoni ezizigidi ezingama-60.Nangona inani lempahla ethunyelwa ngaphandle liphezulu, izinga lokurisayikilishwa lisezantsi.Kusekho ngaphezulu kwe-2/3 yezinto ezilahliweyo ezilahliweyo ehlabathini ezingekakwazi ukuphuculwa kunye nokuphinda zisetyenziswe.

Oku kubizwa ngokuba ngamalaphu anokuphinda asetyenziswe athathwa ngokuba ayarisayikilishwaimpahlaenokuphinda isetyenziswe, kwaye ukusebenza kweemveliso ezenziwe ngokutsha kuyafana, kwaye kunexabiso eliphezulu.amalaphu enye.Kwiimveliso ezilahliweyo “ezilahlwayo” ezinokonakala, ezingenalo ixabiso lezoqoqosho lokuchacha ngokukhawuleza, zinokugalelwa inkunkuma.Ukongeza kule ngcamango yoqoqosho lwesetyhula, ubuchwephesha bemizi-mveliso bohlula-hlula ukurisayikilishwa kube ziindidi ezimbini: ukuphuculwa nokuthoba.

Iindlela zokurisayikilishwa kwelaphu ikakhulu zibandakanya iindlela zoomatshini, zokoqobo kunye neekhemikhali.Indlela yomatshini kukulungisa amalaphu ukuba abe yimicu ebhityileyo okanye iintsinga zokuphinda zisontwe okanye zitshintshe eyona njongo yelaphu;indlela yomzimba yeyokwenziwa ikakhulu kwimicu yokwenziwa, ngakumbi imicu eyenziwe yi-melt spinning, enyibilikiswa kubushushu obuphezulu ukwenza i-textiles inyibilike.Emva kokucoca ukungcola, ziyakwazi ukuphonswa okanye zisetyenziswe kwezinye iimveliso.Ezinye izinto eziphezulu ze-fiber composite ziyakwazi ukususa i-epoxy resin kwiqondo lokushisa eliphezulu, ukubuyisela i-fiber state, kwaye isetyenziswe kwiimveliso ezingezona i-textile ngokusebenzisa iinkqubo zokusika kunye nokutyumza;iindlela zemichiza ubukhulu becala zezohlukeneyo zamalaphu.Ukwahlulwa kweentsinga kuhlaziywa ngokwahlukileyo, kwaye amaxesha amaninzi asetyenziselwa ukuhlambulula izinto ezisetyenzisiweyo, ukususa ngcono ukungcola kunye nedayi, kunye nokuphumeza ukuphuculwa kunye nokuvuselelwa.

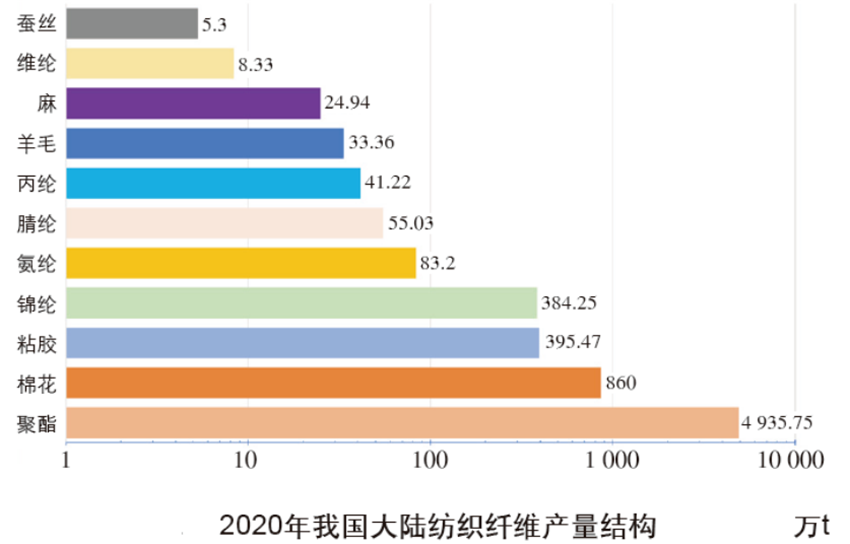

Ngo-2020, i-polyester yelizwe lam i-fiber output ye-49.3575 yezigidi zeetoni, i-72% yetoni iyonke, i-cotton yi-8.6 yezigidi zeetoni, i-akhawunti ye-12%, i-viscose yi-3.95 yezigidi zeetoni, i-akhawunti ye-5.8%, i-akhawunti ye-nylon ye-5.6%.Iifiber eziseleyo zongeza ukuya ngaphantsi kwe-4%.Ukuqinisekisa ukubonelelwa kokutya, imveliso yeentsinga zendalo ezifana nomqhaphu, ilinen, kunye noboya ikwindlela ehlayo iyonke.Sisicwangciso esinezigaba sokutshintsha ezinye iintsinga zendalo ngeentsinga zokwenziwa.Umthombo weemathiriyeli zokwenziwa zefiber ekrwada ungakhetha izibonelelo ezisekwe kwibhayoloji, kunye nemithombo ehlaziyiweyo enokuphinda isetyenziswe kufuneka isetyenziswe ukususa ngokuthe ngcembe ukuxhomekeka okugqithisileyo kwimithombo engahlaziyekiyo.Oku akubalulekanga kuphela ekulondolozeni ubutyebi, ukukhusela okusingqongileyo kunye nokunciphisa ukuhlalwa komhlaba olinywayo, kodwa kubaluleke kakhulu kulwakhiwo nophuhliso loqoqosho olujikelezayo.

Ixesha lokuposa: Feb-27-2023